Barcode readers

Solve manufacturing and logistics applications with industrial, image-based barcode readers and scanners. Our range of barcode readers let you automate visual inspections by identifying and tracking each individual item across your factory, from production to despatch. Achieve full traceability and ensure quality control in any industrial environment, even on high-speed lines handling multiple product lines and variations.

Read 1D and 2D barcodes accurately, every time

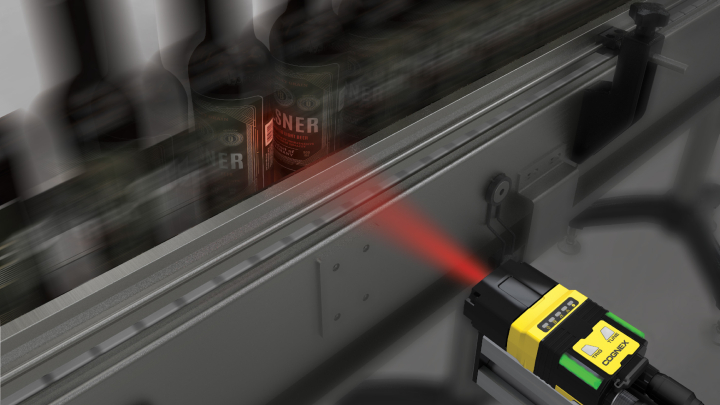

Common types of barcode readers include laser scanners and image-based readers. Laser scanners can produce 1,300 scans/second and read 1-D codes from relatively long distances with the use of special optics. Image-based barcode readers have higher read rates than laser scanners, read 2-D and omnidirectional codes, and capture images of codes for data analysis, process improvement, and barcode quality feedback.

Cognex industrial, image-based barcode readers decode 1D and 2D codes, from printed labels to the hardest to read direct part mark (DPM) codes in manufacturing and logistics. Achieve industry-leading read rates to reduce costs, optimise performance and increase throughput.

Optimise operations with 2X read performance and power

Read 2D codes

Read 2D codes (including QR codes) with significant damage or complete elimination of a code’s finder

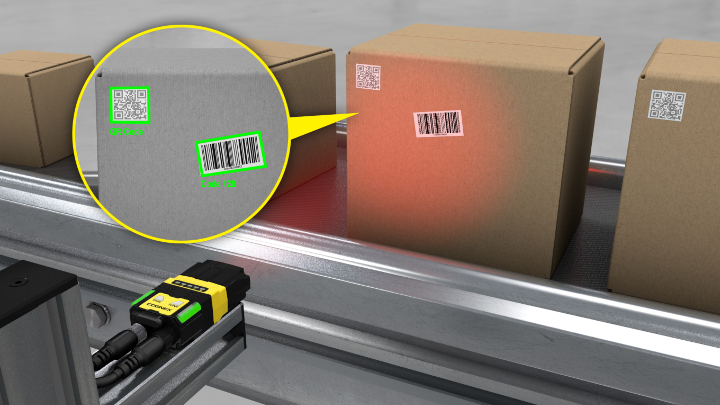

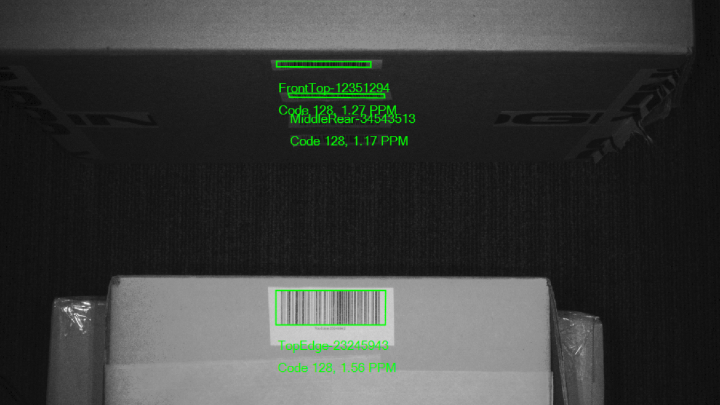

Multiple barcode reading

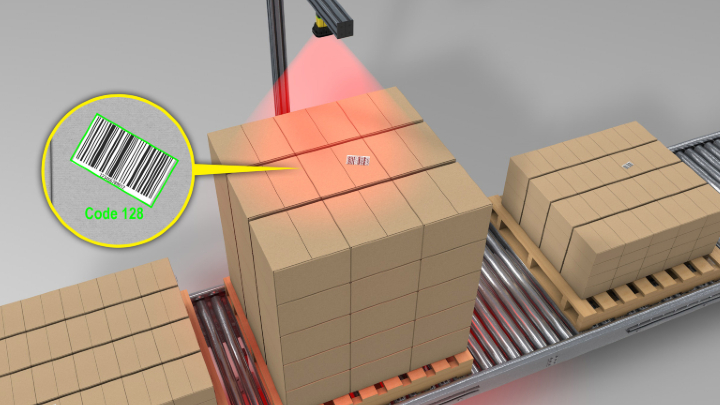

For greater field-of-view and depth-of-field coverage, combined with distance sensor to dynamically focus the lens or trigger the reader.

High-speed inspection

Read multiple barcodes simultaneously on high-speed lines, even behind secular wraps.

Superior image formation

Superior field of view and depth-of-field ensure consistently high read rates to solve wide range of manufacturing and logistics applications.

High-resolution sensors

For greater field-of-view and depth-of-field coverage, combined with distance sensor to dynamically focus the lens or trigger the reader.

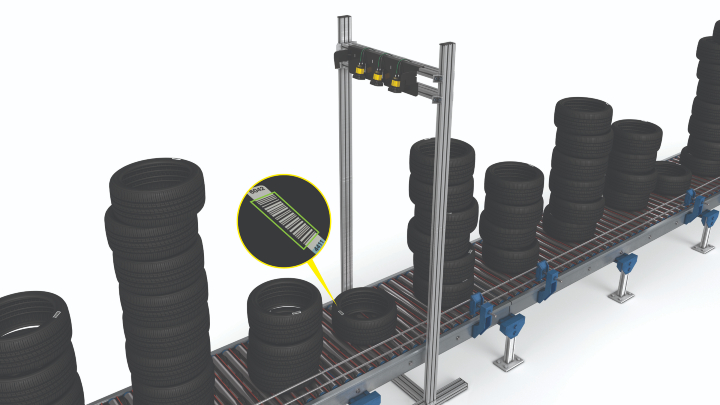

Omnidirectional reading

Features 1D/2D auto-discrimination with omnidirectional barcode reading that works 10X faster than conventional barcode readers.

Rapid deployment

Integration and set up can be completed swiftly with the right vision expertise, even for complex industrial inspections.

High Dynamic Range

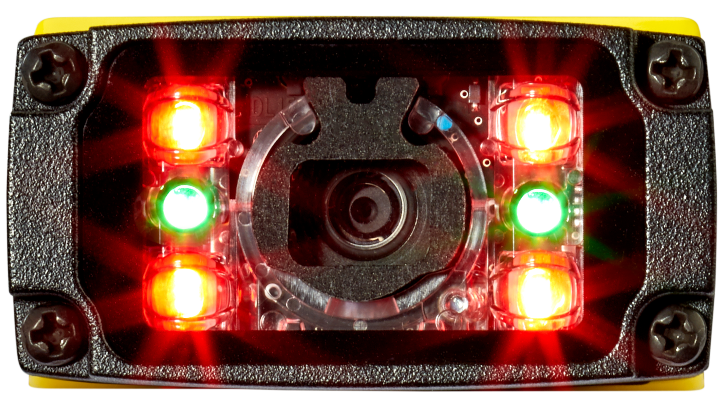

High Dynamic Range (HDR) technology built in, using the latest CMOS image sensor to enhance image quality and contrast.

Built for flexibility

Built with modular components, including lighting, lens and communication options for maximum flexibility.