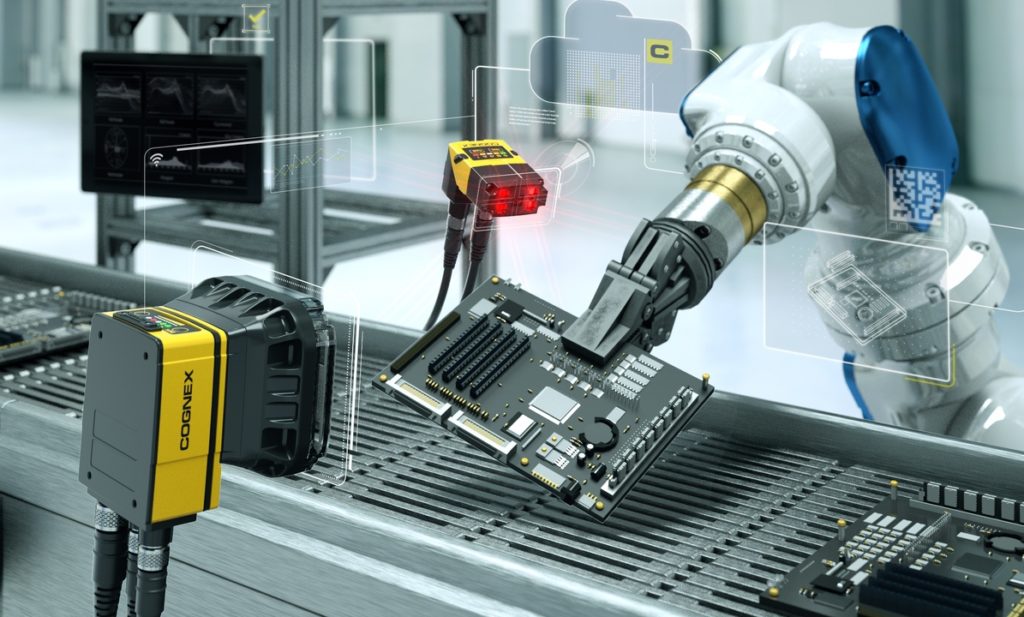

Intelligent vision for faster ROI in automation & robotics

See what's next with Bytronic

With tight margins and economic pressures, investing in automation requires proven return. Intelligent vision is often the first step – faster to implement and showing ROI more quickly than large systems.

The range of emerging technologies creates complexity in finding the right solutions. Bytronic’s vision engineers partner to strike the optimal balance between opportunity and cost.

We rapidly transform processes by embedding intelligent vision that exposes risks, elevates performance, and achieves standardised excellence across facilities. Together we enable your workforce and build resilient operations.

Gain the vision intelligence you need to optimise automaton investments, maximise ROI, and lead confidently into the future. Let us help you act decisively today to automate resiliently for tomorrow.

Leaders trust in our technology

Book a call with our Technical Engineer, George

Optimise your future factory inspections with automation

Solve resource issues

The biggest single issue for any manufacturer is resource. Whatever your industry, product or application, there’s a lack of skilled workers, and that problem is here to stay. Automated vision intelligence can provide a long-term solution to the challenge of hiring people, especially for lower-skilled manufacturing roles.

Prove ROI faster

Cost is always a factor in investment decisions. From finding the right automated solution, at the right price, to getting Board sign off, proving the return on a big system upgrade can take years. A vision system can pay for itself in months, and overcome short-term solutions such as agency costs.

Get started sooner

What good is a new automation or robotics project if it takes months or even years to get started? Lead times and stock positions matter. Vision systems can be specified and set up in just a few weeks, with cameras and hardware already in stock, so you can start automating your applications and seeing results sooner

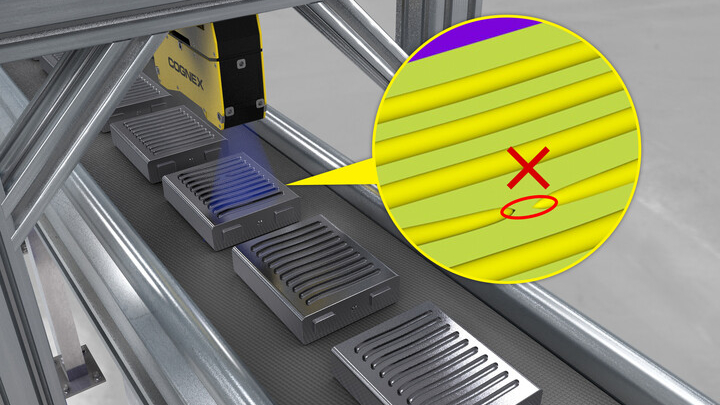

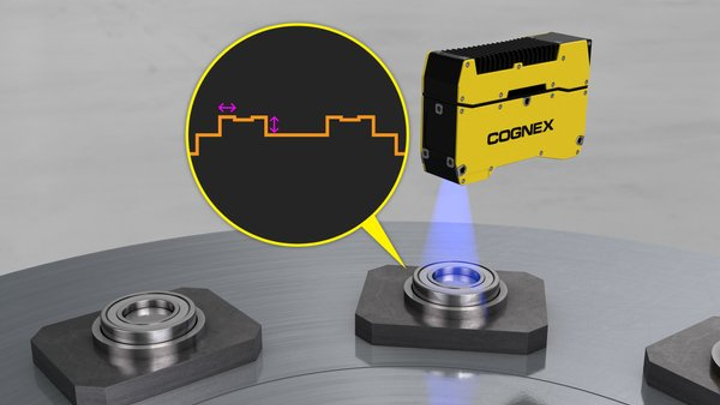

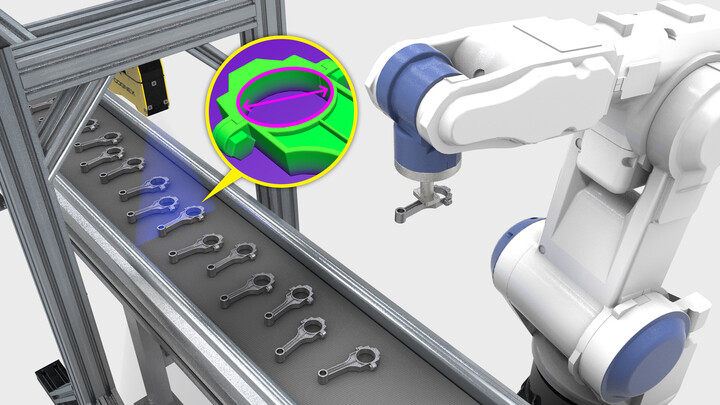

Run complex inspections

Automated vision intelligence can carry out complex and challenging inspections – from 2D and 3D object identification to presence and absence verification, dimensional gauging, high-speed code reading, parts recognition, final assembly verification and much more.

Prevent downtime

In highly regulated or safety-conscious industries, automated vision inspection can reduce the risk of possible safety issues being missed by manual checks. Prevent costly reworks and avoid the risk of reputational damage that comes with product safety recalls.

Get ready for ‘lights-out’

The future of ‘lights out’ automation is fast approaching for all manufacturers. Ignoring the fact won’t work forever. Whatever stage your business is at on its industry 4.0 journey, vision intelligence can help you adopt automation to find efficiencies and stay competitive long-term.