Intelligent vision fuels the automotive future

Amid massive disruption, resilience requires re-engineering processes with intelligent vision. Supply delays and reworks threaten output, while rising costs squeeze margins. As the industry shifts to electric, change accelerates. Legacy issues must be fixed to attain excellence.

Bytronic partners with automotive pioneers on their resilience journey. Our Vision Engineers rapidly re-engineer mission-critical processes to identify risks, reinforce quality, maximise productivity, and enable workforces for the future.

The path forward requires intelligent vision. Let our decades of expertise guide you in re-engineering resilience to unlock efficiency, prevent downtime, and elevate operations for the challenges ahead.

Partner with Bytronic to gain the vision intelligence needed to excel through disruption.

The future of inspection. Intelligent vision.

See the bigger picture

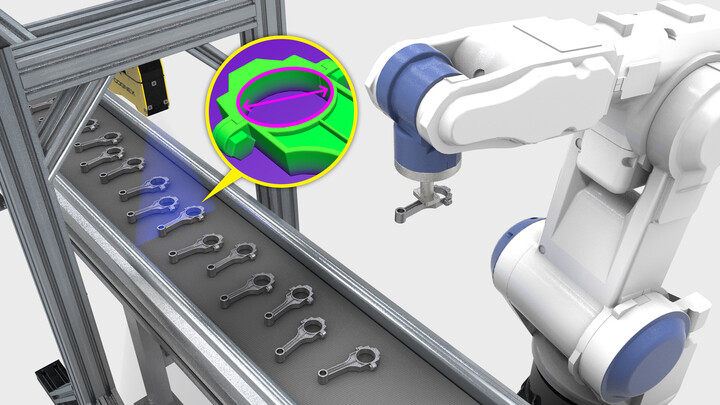

Vision intelligence allows you to turn image-based information into better actions, at any scale. By combining the latest vision technologies with powerful data and predictive insights, automotive manufacturers can optimise production and overcome longstanding production challenges.

Prevent downtime

Every second that an automotive line is stopped costs thousands in production delays, missed deliveries or reputational damage. Vision intelligence can automate and improve quality control to prevent potentially costly manufacturing errors and reduce factory downtime, reworks or recalls.

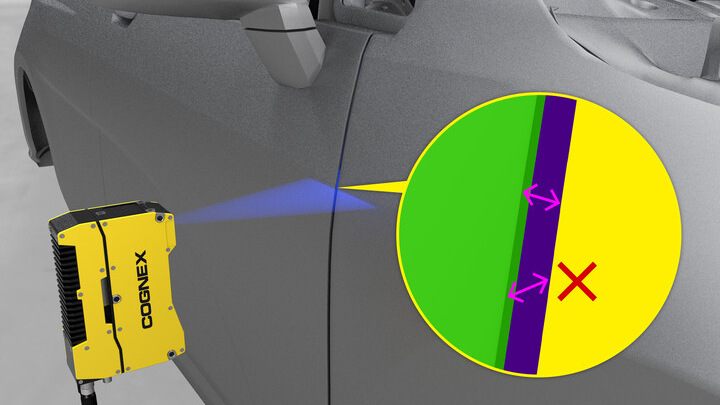

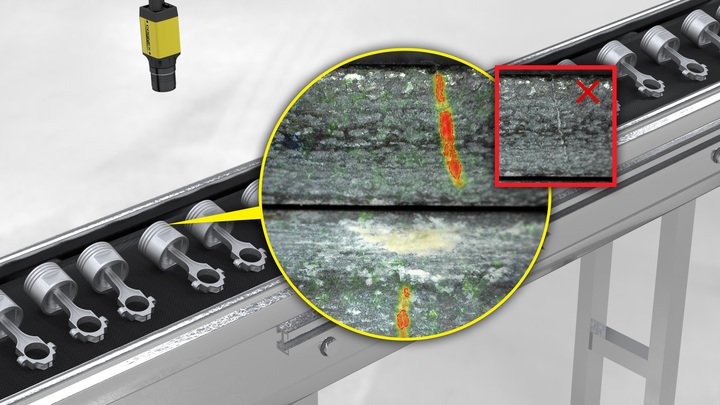

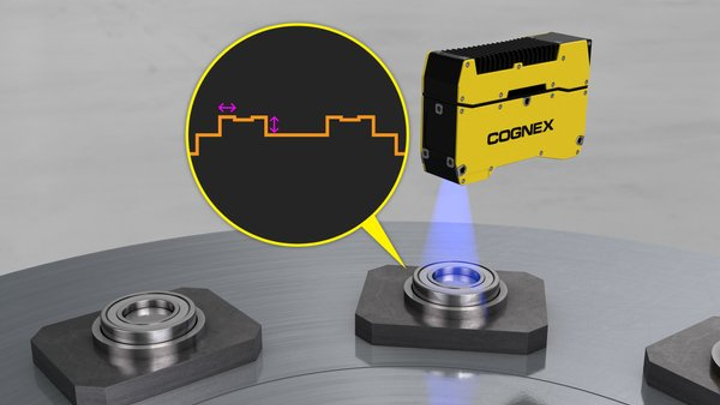

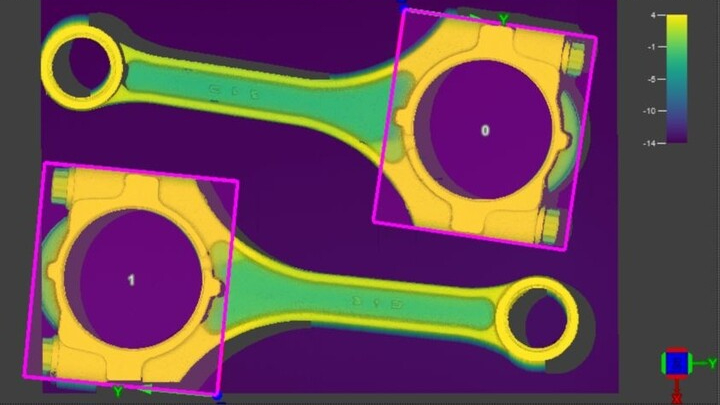

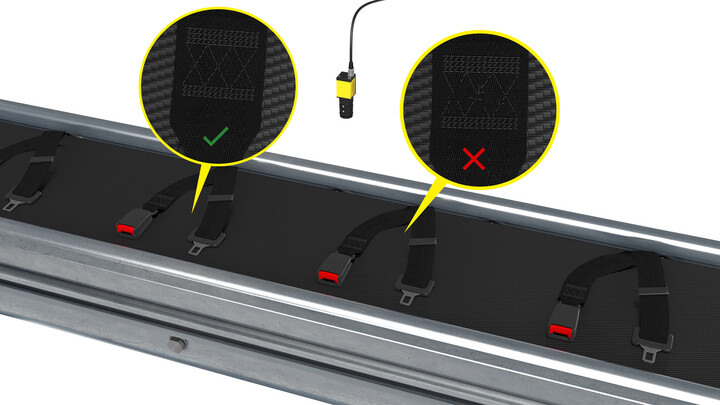

Complex inspections

Vision intelligence can carry out even the most complex surface inspections on vehicle assembly lines – from 2D and 3D object identification to presence and absence verification, dimensional gauging, code reading, parts recognition, final assembly verification and more.

Vision inspection for quality and precision in vehicle assembly

Automate quality control

Spot missing parts or defects, catch operator errors or prevent assembly issues before vehicles leave the factory. With automated vision inspection, quality control systems can ensure precision, strength and reliability in every finished product.

Ensure product safety

In highly regulated and safety-conscious industries, automated vision inspection can reduce the risk of possible safety issues being missed by manual checks. Prevent costly reworks and the risk of reputational damage that comes with product safety recalls.

Future-ready technology

Prevent factory inspection systems becoming outdated with future-ready, connected vision intelligence. Once up-and-running, the latest vision solutions come with regular software updates, to prevent your big technology and automation investments becoming obsolete.