Intelligent vision for manufacturing: to excel in the face of disruption and complexity

Manufacturers face mounting pressures – rising costs, supply chain volatility, sustainability demands, and more. Intelligent vision provides the adaptive solutions to excel through disruption.

Bytronic’s vision engineering integrates predictive capabilities to see what’s next. Our intelligent solutions standardize excellence by:

> Optimising production with data-driven insights to drive efficiency

> Enabling flawless quality control through adaptive machine vision

Providing predictive intelligence to get ahead of future challenges

We empower resilient, future-ready operations. Bytronic’s intelligent vision allows manufacturers to:

> Automate inspections with unlimited potential as technology advances

> Continuously improve processes across facilities worldwide

> Unlock lasting performance to remain competitive amid constant change

As vision engineers, we re-engineer manufacturing to thrive through today’s challenges and tomorrow’s disruptions. Bytronic delivers the intelligent vision to transform your workforce and systems for long-term resilience.

Enabling manufacturers to turn their greatest challenges into opportunity

Find energy efficiencies

Tackling rising prices by getting it done right first time, every time – improving production monitoring to reduce the need for reworks.

Manage materials

Improving quality control pre and post production to cut out reworks or wastage when supplies are scarce or prices are soaring.

Hit sustainability targets

Reducing environmental impact and controlling wastage or reworks – using data analysis and factory insights to find efficiencies.

Tough inspection solutions that are built to handle extremes

Solve resource issues

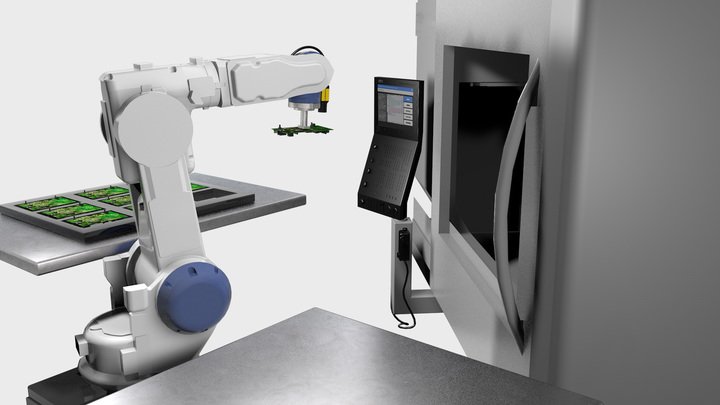

The biggest single issue for any manufacturer is resource. Whatever your industry, product or application, there’s a lack of skilled workers. Machine vision can help maintain production with a smaller workforce, as a long-term solution to the challenge of recruitment.

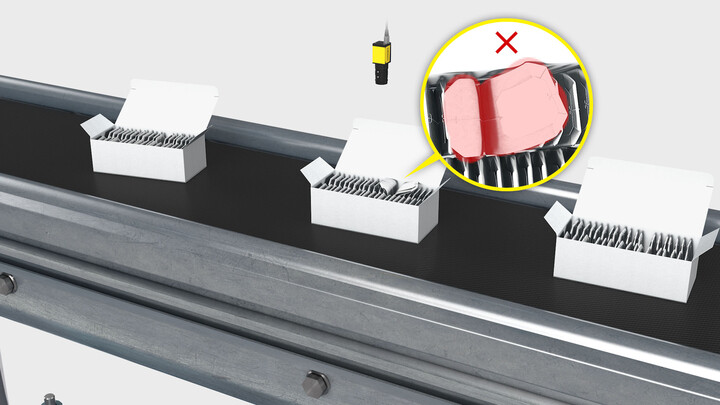

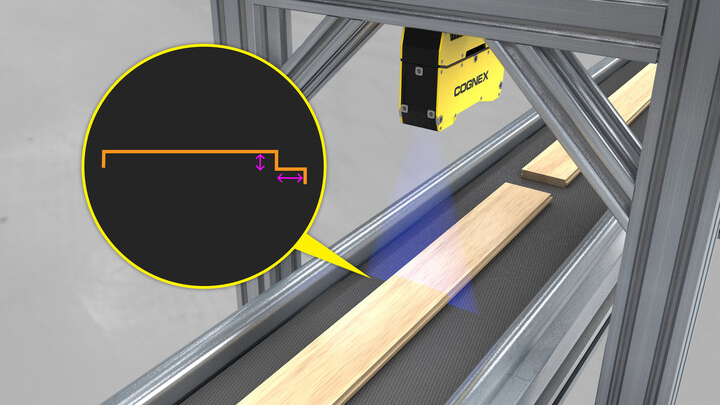

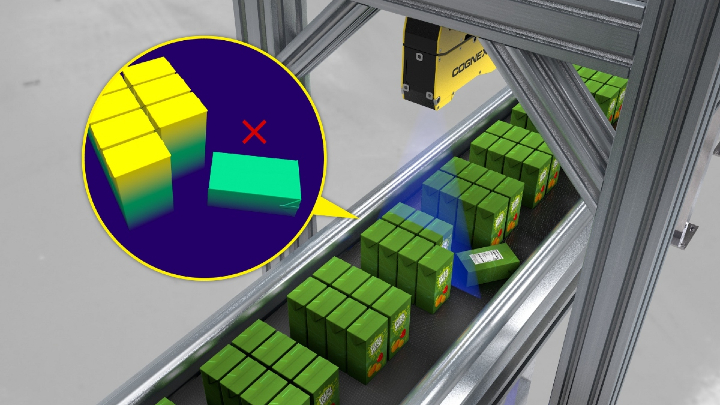

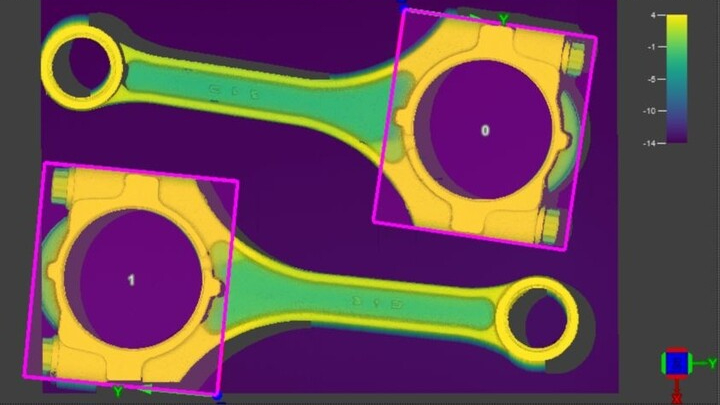

Automate quality control

Spot missing parts or defects, catch operator errors or prevent assembly issues before vehicles leave the factory. With automated vision inspection, quality control systems can ensure precision, strength and reliability in every finished product.

Get ready for ‘lights-out’

The future of ‘lights out’ automation is fast approaching for all manufacturers. Ignoring the fact won’t work forever. Whatever stage your business is at on its industry 4.0 journey, vision intelligence can help you adopt automation to find efficiencies and stay competitive long-term.