Thermal cameras

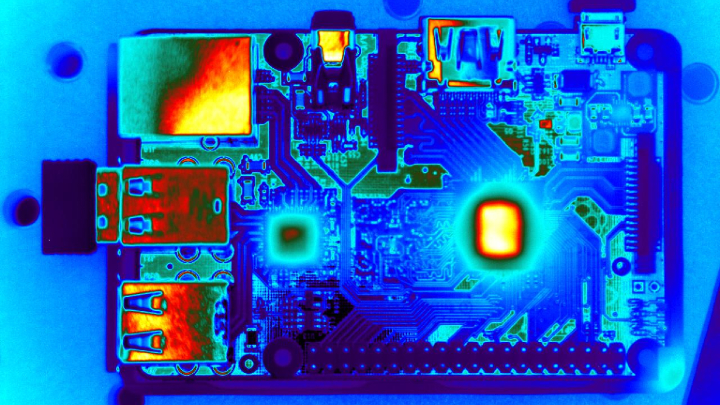

Thermal imaging cameras play a crucial role in detecting and monitoring Infrared radiation (IR) or infrared light, which remains invisible to the human eye. By capturing and visualising IR, these cameras generate images that reveal heat patterns, much like how standard cameras use visible light.

There are two main types of thermal cameras available: thermal temperature cameras and thermal infrared cameras. Thermal temperature cameras are primarily used to monitor temperature variations, while thermal infrared cameras excel in detecting and monitoring thermal energy.

These cameras offer valuable insights and facilitate the automation of process inspections, ultimately enhancing quality control measures. Furthermore, they serve as indispensable tools in safeguarding high-risk facilities where fire safety stands as a paramount concern.

Accurate, non-contact quality control

Non-contact quality control

Use thermal for a fully automated, non-contact quality control system – ideal for hot melt glue application inspection.

Accurate inspection

Cooled IR cameras can accurately inspect detailed or fast moving objects – ideal for stress testing materials in factory settings.

Turnkey industrial solutions

Automate a wide range of factory applications with thermal temperature monitoring in factory settings or extreme environments.