Human-level precision in inspection and application with deep learning

Deep learning enables our vision engineers to architect complex solutions that replicate human-level analysis. By leveraging GPUs and accessible software tools, we can rapidly teach intelligent vision systems to execute sophisticated inspections, regardless of variations.

Once integrated, these solutions can be reliably operated without needing extensive AI or programming expertise. Where highly customised anomaly detection and tight tolerance demands exist, deep learning thrives. It analyses extensive training data to automate challenging tasks with precision approaching human specialists.

Partner with our vision engineers to embed accessible deep learning that exposes risks, elevates performance, and achieves standardised excellence. Together we’ll strengthen operations that enable workforces ready for disruption.

Deep learning delivers unmatched intelligence

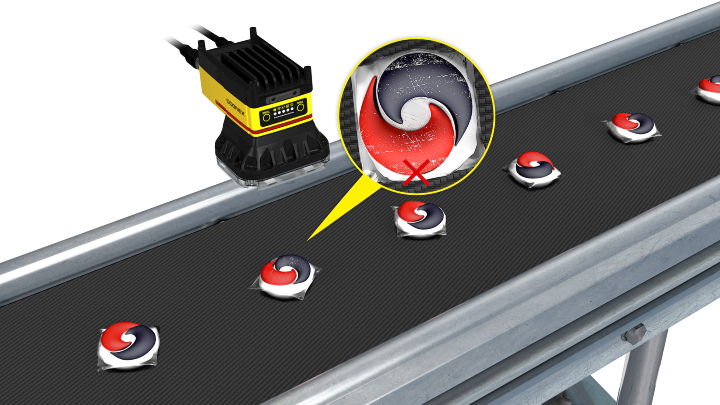

Complex defect detection

Automating defect detection has long been a challenge. Deep learning can now identify complex product defects quickly and reliably.

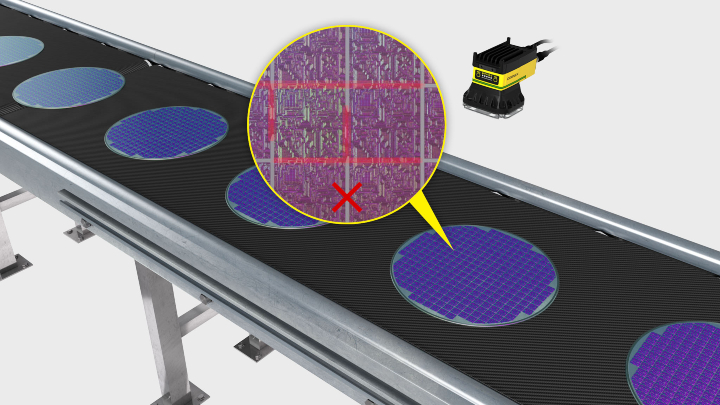

Detailed surface inspection

Check for surface damage, errors or abnormalities – such as inspection of paintwork, textiles, printed text or car body parts

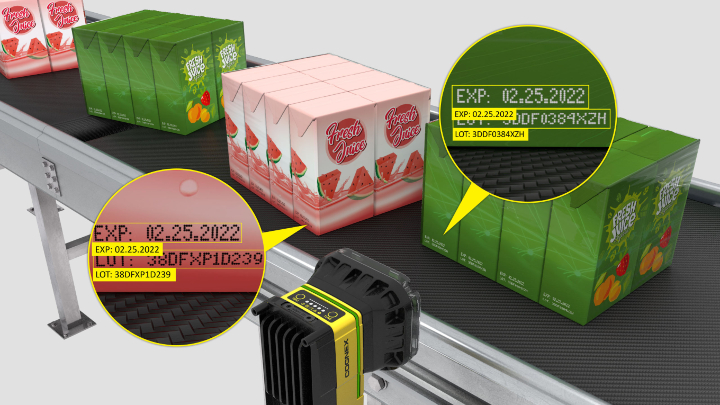

Highly customised lines

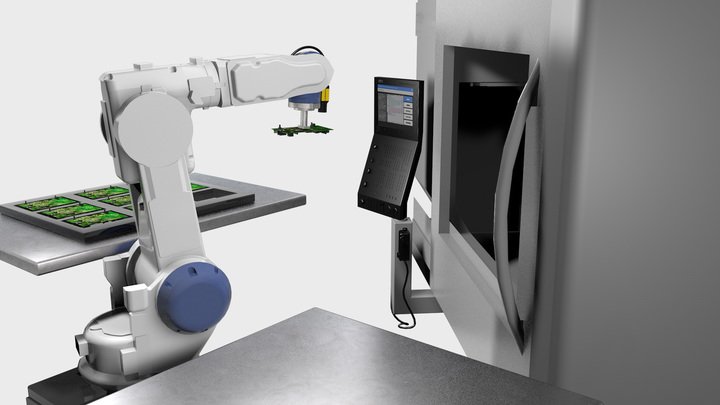

For production lines handling multiple product types, variations or tasks, deep learning can easily handle complex inspections.

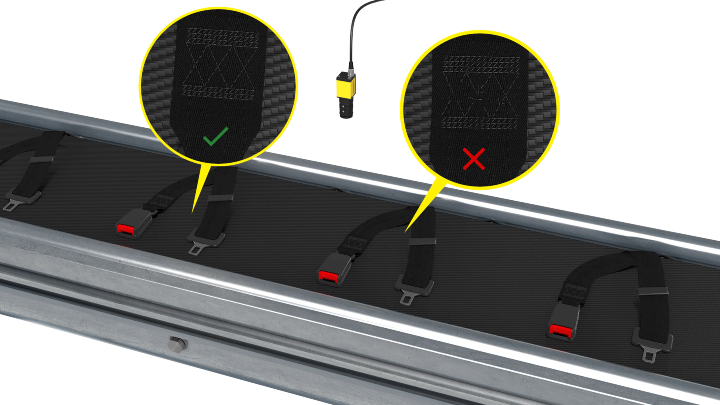

Complex categorisation

Detect damage on car body panels, spot upside-down products or catch misshaped foods on fast-moving conveyors

Deploy with expertise

Deep learning inspection & application is best set up & trained by vision intelligence experts, ready for factory engineers to work with.

Get ready for 'lights out'

The future is ‘lights out’ automation – adopt deep learning to find efficiencies and remain competitive long-term.