Intelligent vision for food and beverage: for product safety & traceability

Food and beverage leaders face growing scrutiny—from shifting regulations to consumer demands for sustainability. Ensuring safety and traceability remains imperative but increasingly difficult.

Changing trends like bespoke packaging add complexity across raw materials, product integrity, and waste. Manual methods strain under volatility.

Bytronic’s vision engineers rapidly transform processes by embedding intelligent vision. Our solutions expose risks while elevating performance through automation. We partner to re-engineer operations, achieve standardised excellence, and build resilient workforces.

Gain the vision intelligence to drive efficiency, enable traceability, and excel through disruption.

Smart solutions to tackle your toughest challenges

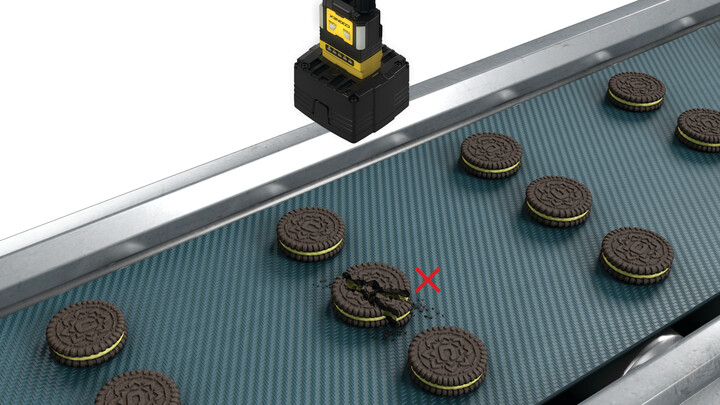

Protect product quality

Monitoring raw materials in real-time can catch potential defects early, improving productivity and reducing wastage or costly extra reworks. Vision intelligence can inspect product volumes or quantities, check for missing items or use the latest deep learning technology to automate previously ‘human’ inspections such as product variation or cosmetic damage.

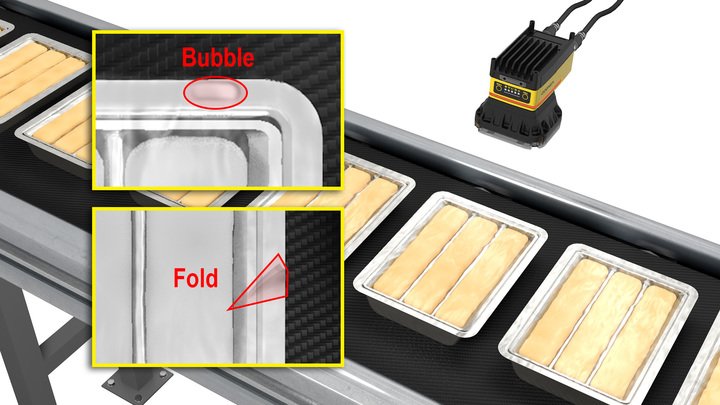

Hit sustainability goals

Reducing or removing plastic from the manufacturing process while ensuring pack stability is a real challenge, especially when consumers continue to demand single-use products. Vision inspection can check pack integrity on lines where plastic has been replaced by hot melt glue and prevent wastage through rapid inspection for perishable goods.

Prove full traceability

Showing and proving product traceability is crucial for quality, consumer safety and reputation. Vision intelligence can follow products through the supply chain, checking batch codes, tracking allergens and ensuring the correct product labelling to give retailers and consumers confidence in your products. And make future recalls easier to trace.

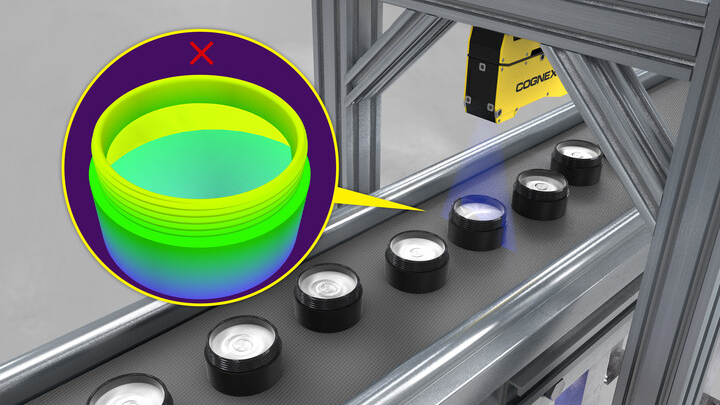

Protect product quality

Automated machine vision intelligence can carry out simple or complex and inspections – from fill level inspection or product inspection to high-speed label or code inspection, optical character recognition (OCR), 2D and 3D object identification, sortation, presence or absence verification and much more.

Automate quality control

Spot missing parts or defects, catch operator errors or prevent assembly issues before products leave the factory. With automated vision inspection, quality control systems can ensure repeatability and reliability in every finished product.

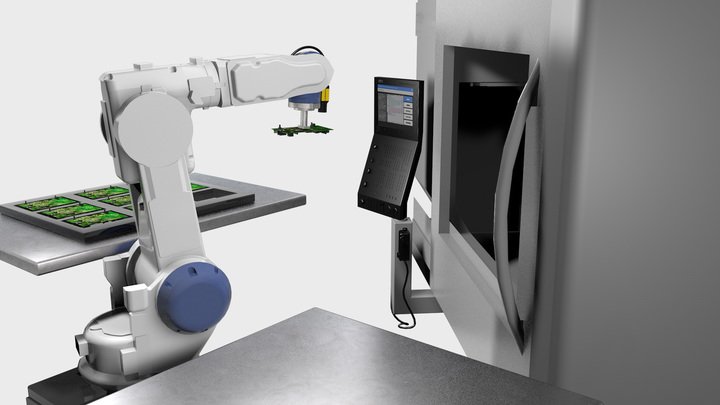

Get ready for ‘lights-out’

The future of ‘lights out’ automation is fast approaching for all manufacturers. Ignoring the fact won’t work forever. Whatever stage your business is at on its industry 4.0 journey, vision intelligence can help you adopt automation to find efficiencies and stay competitive long-term.