Machine vision: The core technology in advancing industrial automation

Bytronic’s vision engineers rapidly transform processes by embedding intelligent vision, including AI and deep learning. Now this proven technology is merging with AI, leading the transition to Industry 4.0.

For over 25 years, we have combined technologies from partners like Cognex and FLIR to customise solutions that expose risks, elevate performance, and achieve standardised excellence across operations.

Partner with us to gain the intelligent vision systems that drive efficiency, prevent defects, and empower workforces. Together we strengthen mission-critical processes to attain new levels of quality, traceability and productivity.

Intelligent vision delivers powerful improvements

Improving quality control

Spot defects or missing or misplaced items earlier in the production process, to prevent issues later on.

Prevent human error

Remove manual checks from your manufacturing process to stop relying on people for repetitive, repeatable tasks.

Increase outputs

Carry out inspections at high-speeds to limit factory downtime and keep your machines running for longer.

Reduce wastage

Limit the cost of recalls, reworks and wastage to your business, in terms of time, materials, energy and shipping.

Overcome labour shortages

Machine vision can be used to automate manual processes at times when recruitment is a big challenge.

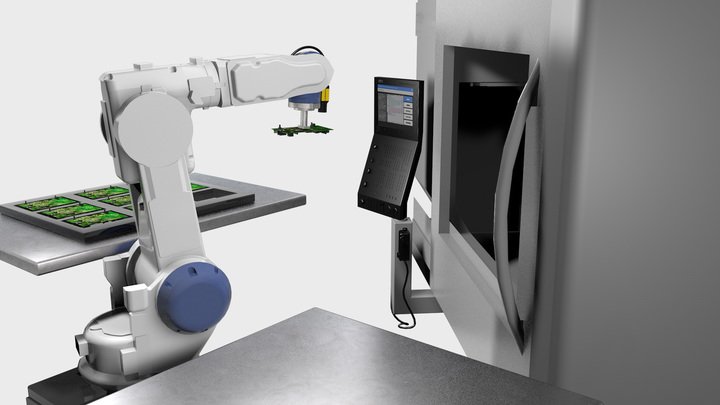

Get ready for 'lights out'

The future is ‘lights out’ automation – adopt automation to find efficiencies and remain competitive long-term.

Embedding intelligent vision where it has the greatest operational impact

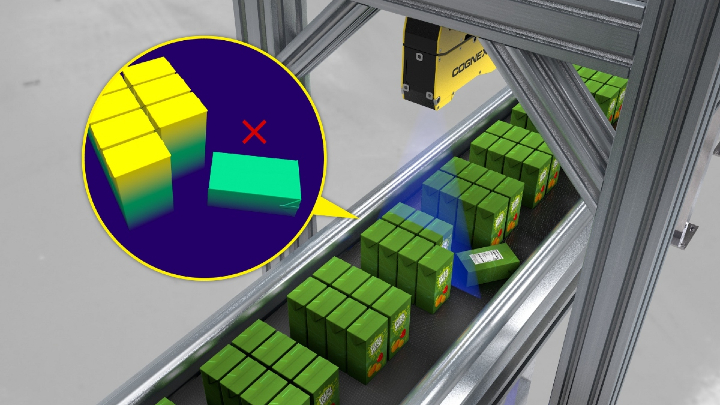

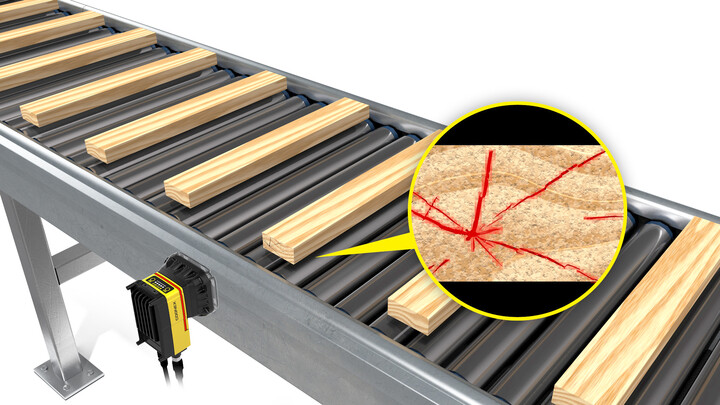

100% inspection

Protect your brand by preventing substandard or mislabelled products leaving your factory

- Reduce defects

- Increase yields

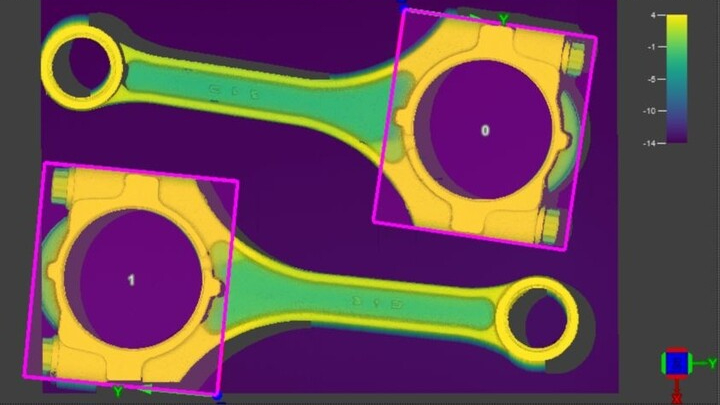

Gauging

Non-contact high accuracy measurement

Verify tolerances on parts, assemblies and product labels with high-accuracy, non-contact measurement

• Automated, documented gauging

• Measurement of fragile items

Identification

99.9% read-rates

Dramatically reduce the impact of no-reads with industry-leading read rates and realtime feedback:

• Avoid costly no-reads

• Reduce rework hours

Verification

Optical character verification

Have absolute confidence in the accuracy and readability of your data and SKUs with Optical Character Recognition

• Legal compliance

• Safety critical information

Trouble-shooting

Machine diagnostics using high-speed cameras

Review machine jams, crashes and failures frame-by-frame using recording speeds of up to 10,000 fps

• Identify persistent equipment issues

• Save engineering time