Unlock AI-powered efficiency effortlessly in minutes with edge vision

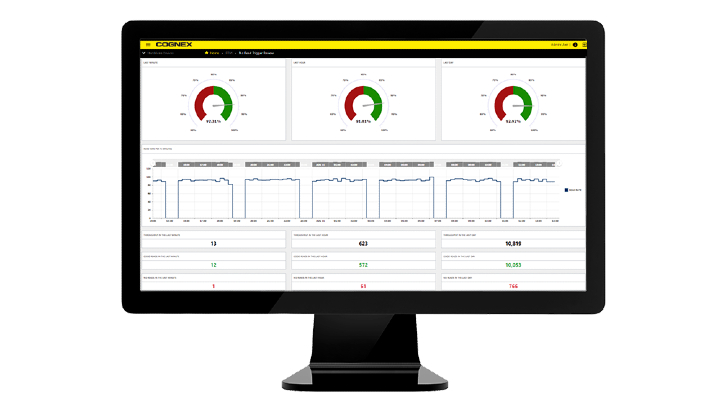

Edge vision embeds simplified AI tools inside smart cameras to automate a wide range of inspections rapidly. Our vision engineers leverage edge vision to expose risks, elevate performance, and achieve standardised excellence across your operations.

Requiring minimal training data, edge vision solutions start delivering value in minutes. The streamlined approach integrates seamlessly without extensive previous experience, transforming mission-critical processes through easy inspection automation.

Partner with Bytronic to deploy edge vision where intelligent automation has the greatest operational impact. Together we can strengthen your most crucial processes and build future-ready workforces that excel through disruption.

Edge vision delivers instant intelligence

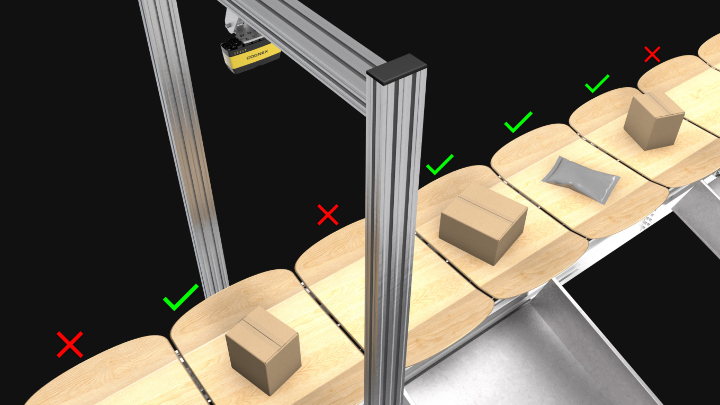

Automate repeatable tasks

Edge vision can automate many simple, repeatable or repetitive factory inspections or applications with ease.

Wide range of uses

Edge vision can automate defect detection, product sortation, assembly verification, character reading and more.

Powerful hardware

Edge learning hardware come with built-in lighting, high-speed autofocus lens and powerful sensor all within a single smart camera.

Simple to use

No previous programming experience is needed for set up – edge vision can be easily setup or quickly adjusted.

Deploy in minutes

Edge vision solutions come pre-trained and can be set up in minutes without a PC, using just a few images.

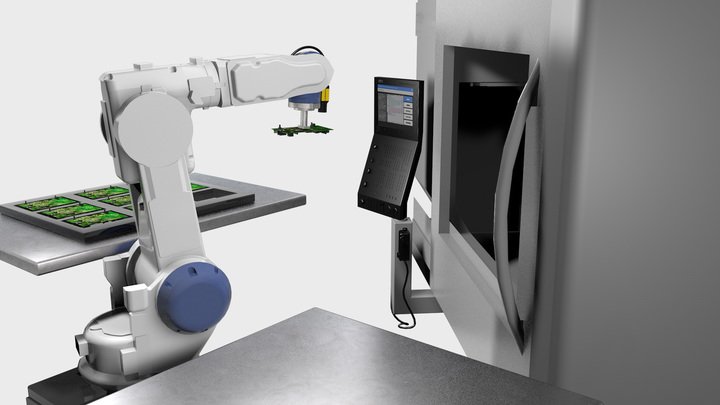

Get ready for 'lights out'

The future is ‘lights out’ automation – adopt edge vision to find efficiencies and stay competitive long-term.