Expose invisible risks with thermal imaging

Thermal imaging for inspection and monitoring

Thermal imaging enables our vision engineers to detect risks and opportunities not visible to the human eye. By monitoring infrared radiation, thermal cameras can automate inspections to enhance quality control and safeguard facilities.

Whether ensuring precise temperatures or detecting thermal events, thermal imaging provides unique operational insight. We embed this intelligence where it has the greatest impact – empowering workforces, preventing downtime, and executing excellence.

Leaders trust in our technology

Book a call with our Technical Engineer, George

Things to consider before deploying thermal imaging:

- What material is the object?

- Is it moving or stationary?

- What are the target and ambient temperatures?

- Do you need to monitor temperature or just detect the object?

Thermal imaging safeguards your operations by delivering instant insight

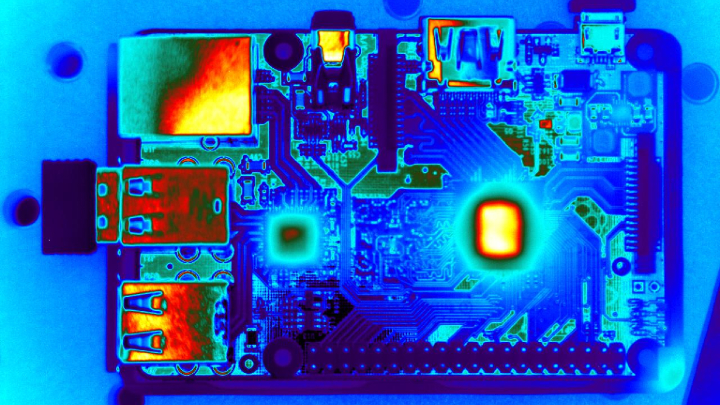

Non-contact quality control

Use thermal for a fully automated, non-contact quality control system – ideal for hot melt glue application inspection.

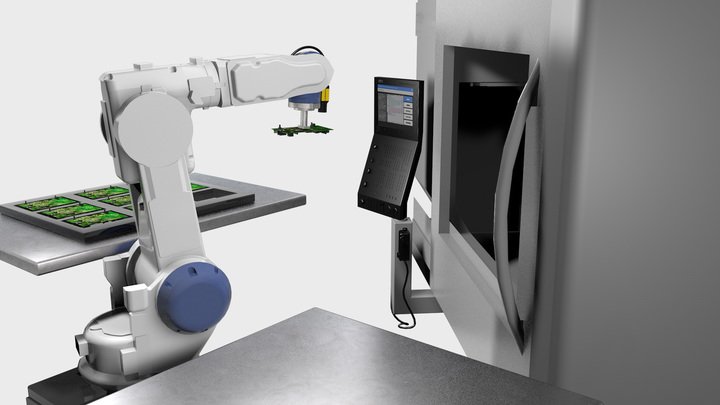

Turnkey industrial solutions

Automate a wide range of factory applications with thermal temperature monitoring in factory settings or extreme environments.

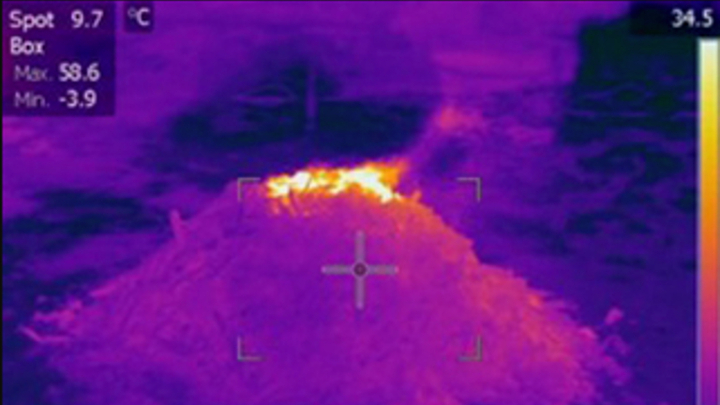

Early fire detection

Detect fires before they start – spot elevated temperatures at high-risk sites with 24/7, real-time thermal inspection.

Powerful technology

The latest thermal imaging cameras feature dual spectrum technology, combining thermal and visual inspection in one smart camera.

Accurate inspection

Cooled IR cameras can accurately inspect detailed or fast moving objects – ideal for stress testing materials in factory settings.

Get ready for 'lights out'

The future is ‘lights out’ automation – adopt automation to find efficiencies and remain competitive long-term.