On production lines where batteries are required, fire safety is key.

Thermal runaway blazes in factories can be catastrophic, so continuous monitoring is crucial to prevent potential fires.

The risk of battery fires

If a battery’s temperature increases to over 150℃, it can start to break down or chemically change. Should this happen, they can catch fire and burn at over 600℃, making them extremely dangerous.

It’s for this reason that EV manufacturers in particular are installing thermal cameras focused on batteries throughout the production line and linking them to fire detection systems to avoid any issues.

The solution

Continual monitoring of batteries throughout the manufacturing process is crucial.

In EV assembly, battery monitoring is especially important at the point when cells are being put into the vehicles and when attaching the wiring harnesses and connections to the cell. The same can be said for the electronics industry and other sectors where batteries are used in products.

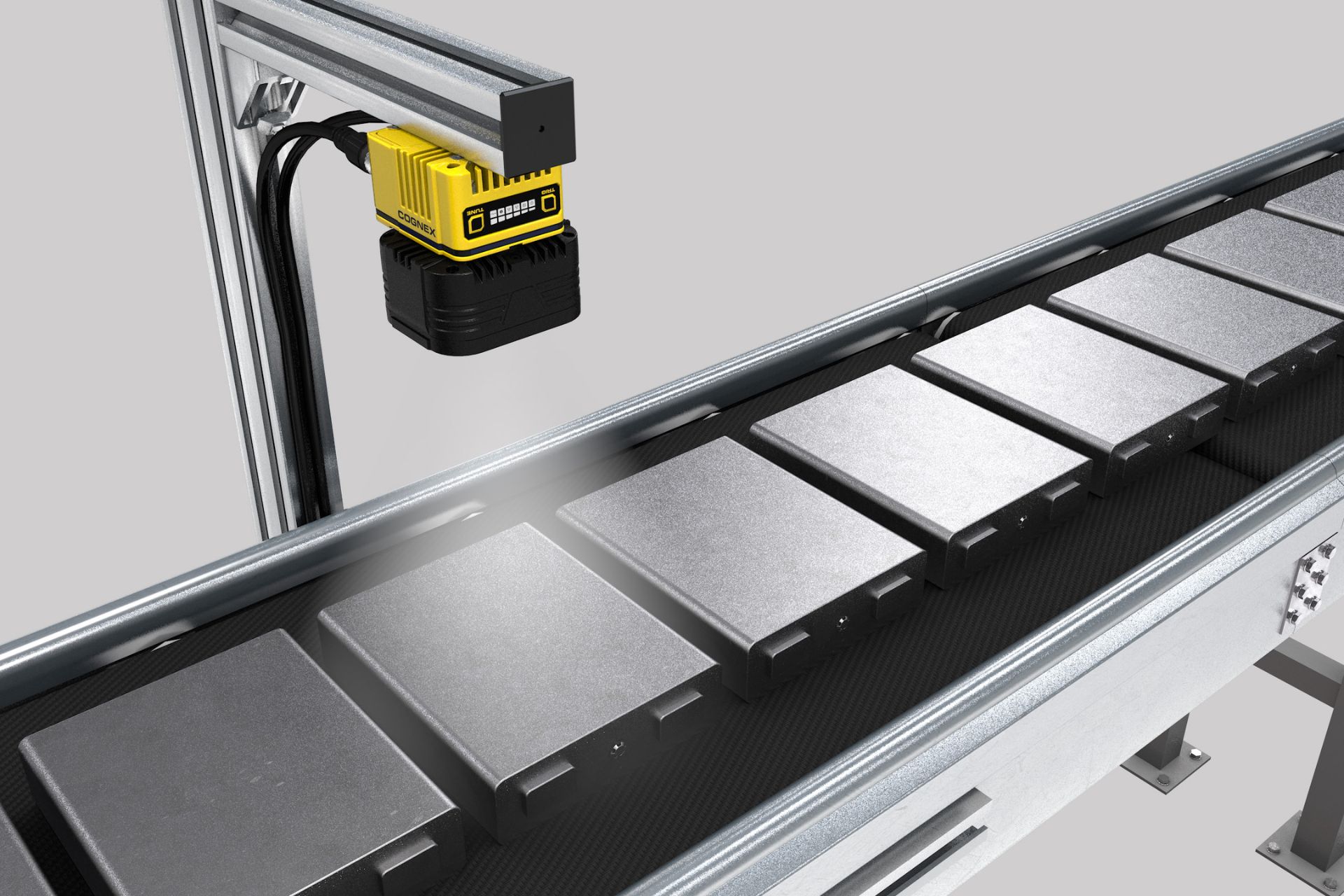

By using automated thermal imaging to constantly monitor batteries at key points of the production line, manufacturers can ensure there are no sparks or sudden drains on the battery which can cause it to heat up and potentially lead to thermal runaway.

Thermal cameras are smart devices capable of analysing temperatures and identifying problems independently. They can then communicate that information over a network and share the maximum temperatures with PLCs and fire detection systems.

The benefits

Some companies are still doing battery inspection manually. They will have a handheld thermal camera that requires someone to periodically check each and every battery, which is time consuming, costly and unreliable. Not to mention a risk to life should something go wrong.

By installing fixed thermal cameras in specific locations, the batteries can be constantly monitored and information is automatically shared.

This saves time and money for manufacturers, and is also a much safer process, meaning nobody has to be sent in to check on a potential fire risk. It is a highly accurate system and eradicates the risk of human error.

Get in touch with us to discuss how we can use the latest thermal technology to install a complete battery inspection system to your production line.