When it comes to vision systems, understanding the concept of field of view (FOV) is essential. It determines what your camera can see and affects how you analyse images in machine vision applications.

In this blog post, we’ll break down the importance of field of view, explain its relevance in industrial automation, and explore how to choose the right field of view for your application using insights from the Cognex Lens Advisor tool.

What is the field of view?

Field of view refers to the area that your camera lens can capture in a scene or object. It’s like the camera’s viewing angle.

A wider FOV covers more space but sacrifices some detail, while a narrower FOV captures more detail but focuses on a smaller area.

Why field of view matters in industrial automation

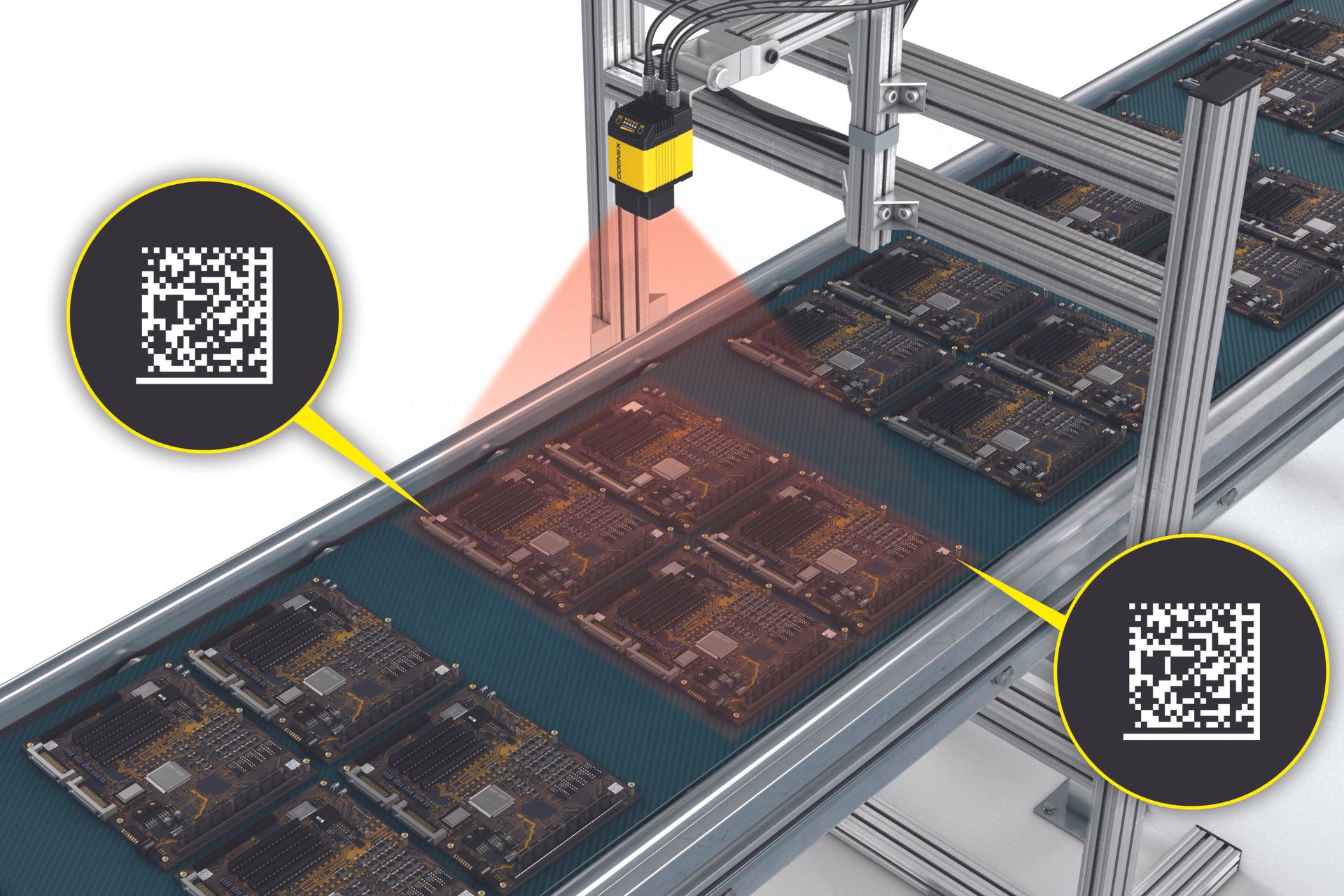

Field of view plays a crucial role in industrial automation, where vision systems are used for quality control, inspections, and robotics.

Having the right FOV ensures that you capture important features and defects with enough detail. This is crucial for making accurate decisions in real-time production environments.

How to choose the right field of view

When choosing the right field of view for your application, keep these factors in mind:

- Object size: Consider the size of the object you’re inspecting or analysing. Make sure it fits within the FOV. If the object is too big, you may need multiple cameras or a wider-angle lens.

- Working distance: The distance between your camera and the object affects the FOV. If you’re closer, the FOV will be smaller. If you’re further away, you may need a narrower FOV to maintain image clarity.

- Resolution requirements: Determine the level of detail or resolution you need for your application. Higher resolution often requires a narrower field of view to capture finer details.

To make things easier, Cognex offers a handy tool called the Lens Advisor. It’s an interactive tool that helps you select the right lens and field of view. Just enter your camera and application-specific parameters, and it will provide recommendations tailored to your needs.

By understanding the relationship between FOVand your application requirements, you can optimise your vision system. This ensures accurate data capture, minimises errors, and boosts overall system performance and productivity.

Bytronic Vision Intelligence has decades of experience, through hundreds of vision applications. If you have a vision application, contact us and we can work with you to find a solution.