Intelligent vision for accelerated, elevated and more reliable heavy industry operations

In extreme environments, automation requires rugged, reliable inspection to replace manual checks. Intelligent vision thrives where human oversight strains.

Bytronic’s vision engineers rapidly transform mission-critical processes by embedding intelligent vision purpose-built for harsh conditions. Our solutions expose risks, enable traceability, and achieve standardised excellence across facilities.

Together we strengthen operations, prevent downtime, enhance quality, and empower resilient workforces ready for what’s next.

Tough inspection solutions that are built to handle extremes

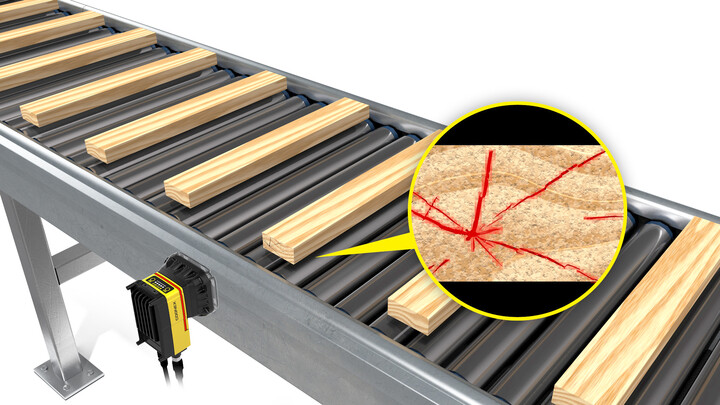

Ensure repeatability

Repeatability is the biggest issue for many heavy or bulk materials industries. The product has to be the same every time for the material to perform – particularly true of safety materials or heavy metals. Automated vision can remove the need for labour-intensive manual checks and prevent human error.

Solve resource issues

The biggest single issue for any manufacturer is resource. Skilled maintenance engineers can often be in short supply, so being able to leave lines running 24/7 is so important. Automated vision intelligence can provide a long-term solution to the immediate challenge of resource – and all of the difficulties that come with it.

Find efficiency savings

Manage rising prices or material scarcity by getting it done right first time, every time. Vision intelligence can improve quality control before and after production, reducing the need for reworks and preventing wastage when supplies are scarce or prices are soaring.

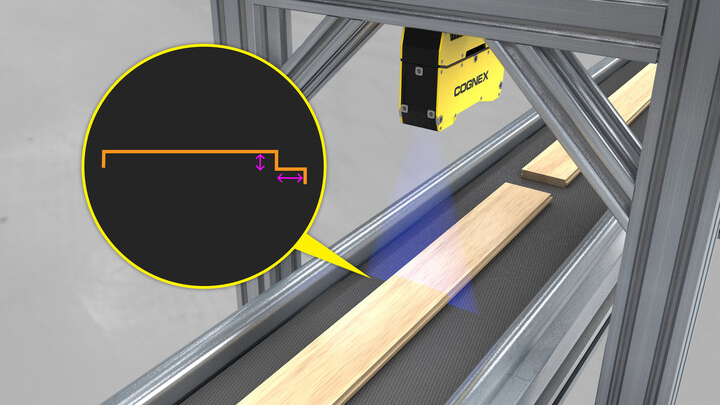

Run complex inspections

Automated vision intelligence can carry out simple or complex and inspections – from high-speed label or code inspection and optical character recognition (OCR) to 2D and 3D object identification, sortation, presence or absence verification, parts recognition and much more.

Prevent downtime

Downtime can have a huge impact on any business, but few more so than in heavy and bulk materials industries. Automated vision inspection can reduce the risk of downtime occurring, and prevent human error, reducing possible product safety issues slipping past traditional manual checks.

Ensure traceability

Showing and proving product traceability is crucial for quality, safety and reputation. Vision intelligence can follow products through the supply chain, checking batch codes and ensuring the correct product labelling to give customers confidence in your products. And make future recalls easier to trace.