Intelligent vision for consumer goods: for exceptional consistency in quality & safety

Manufacturers of fast moving consumer goods face massive disruption—from people shortages and rising costs to supply chain instability. Threats to productivity and profitability loom large.

Achieving absolute consistency in quality and safety remains imperative. Consumer trust and the bottom line depend on it. But manual methods strain under complexity.

Bytronic’s vision engineers rapidly transform mission-critical processes by embedding intelligent vision. Our solutions expose risks while elevating performance through automation. We partner to re-engineer operations, achieve standardised excellence, and empower resilient workforces.

Transform global manufacturing productivity

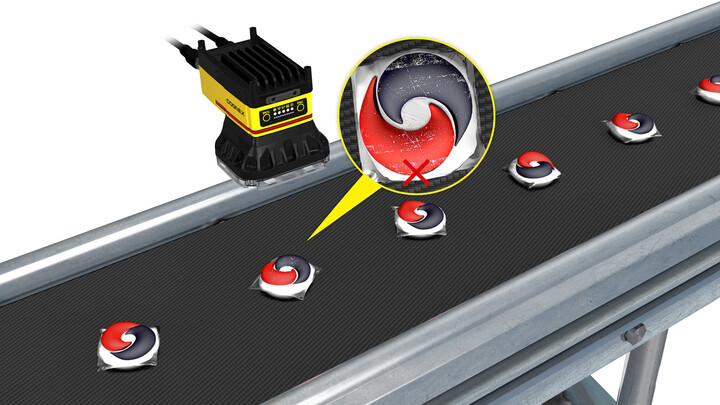

Ensure product safety

Ensuring safe, reliable products is the single biggest priority for any FMCG manufacturer. No business wants to risk consumer health, customer confidence or reputational damage. Vision intelligence can automatically inspect production lines for pack seal integrity, check for possible contamination, incorrect labelling, seal allergen tracking and more.

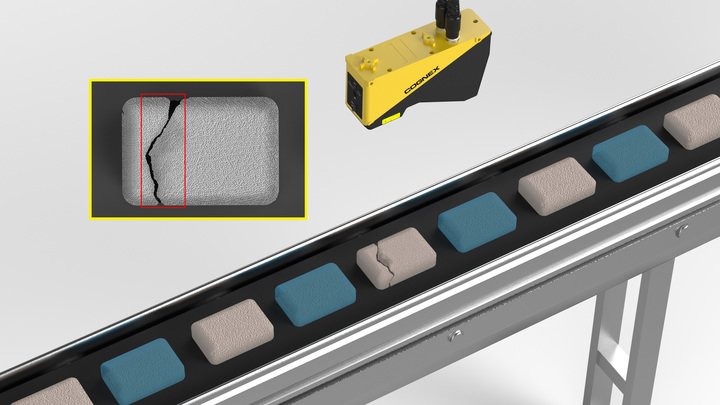

Maintain product quality

Maintaining product consistency in high-speed, large volume manufacturing is a big challenge. Doing it cost-effectively through manual inspections is even harder. Vision intelligence can carry out quality control at pace and scale, inspecting every product for consistency, size, cosmetic damage and possible defects, preventing future product recalls or returns.

Improve productivity

Downtime costs money. Protecting, optimising and improving productivity, and reducing line stoppages is essential to staying efficient and competitive. Vision intelligence can transform FMCG productivity before, during and after production using automated inspection and monitoring, to compare performance across single sites or whole continents.

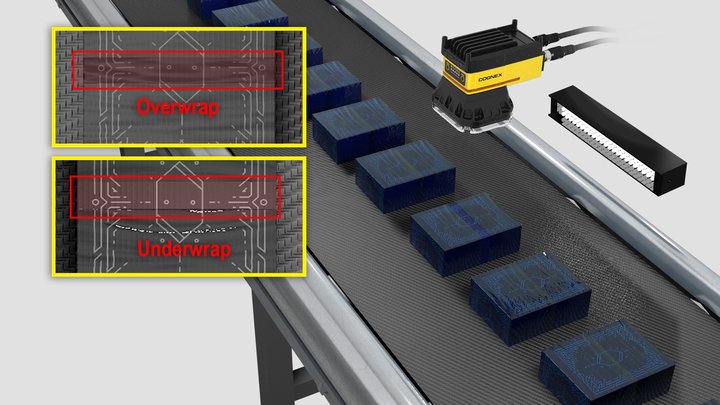

Run complex inspections

Automated vision inspection can carry out simple or complex inspections – from fill level or product inspection to high-speed label or code inspection, optical character recognition (OCR), object identification, sortation, presence or absence verification and more.

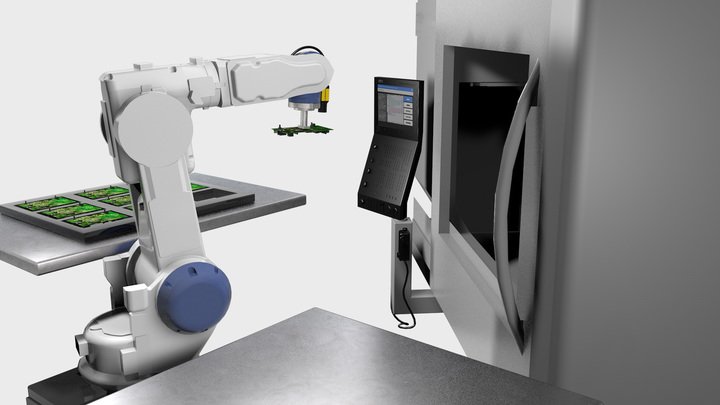

Automate quality control

Spot missing parts or defects, catch operator errors or prevent assembly issues before products leave the factory. With automated vision inspection, quality control systems can ensure repeatability and reliability in every finished product.

Get ready for ‘lights-out’

The future of ‘lights out’ automation is fast approaching for all manufacturers. Ignoring the fact won’t work forever. Whatever stage your business is at on its industry 4.0 journey, vision intelligence can help you adopt automation to find efficiencies and stay competitive long-term.