Cognex 3D-A1000 Dimensioning System

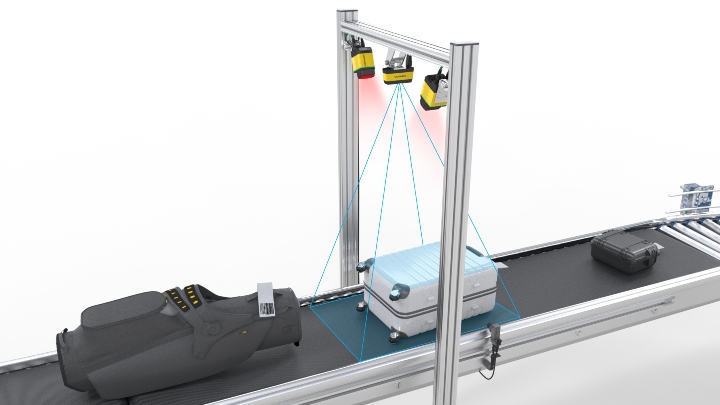

The 3D-A1000 dimensioning system is a compact and industrial smart camera, capable of capturing moving objects in both 3D and 2D. The system is equipped with powerful vision-based tools that automate tasks like container fill measurement, damage detection, feature finding and more.

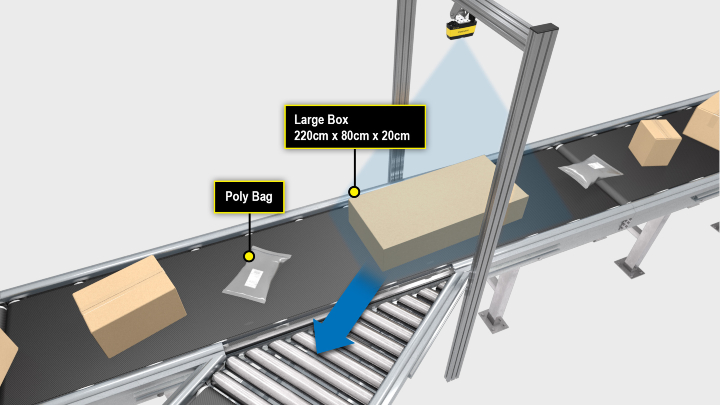

It provides fast, reliable results, enabling logistics sites to estimate shipping costs, optimise storage density, track registered goods, sort products efficiently, recover lost revenue and eliminate manual processes.

The 3D-A1000 uses patented 3D symbolic light technology to freeze motion with a single image – generating accurate 3D point cloud data and eliminating the need for complex calibration. While embedded processing enables the use of powerful Cognex vision tools to run additional 3D + 2D inspections.

Powerful inspections powered by 3D and 2D technology

Wide range of inspections

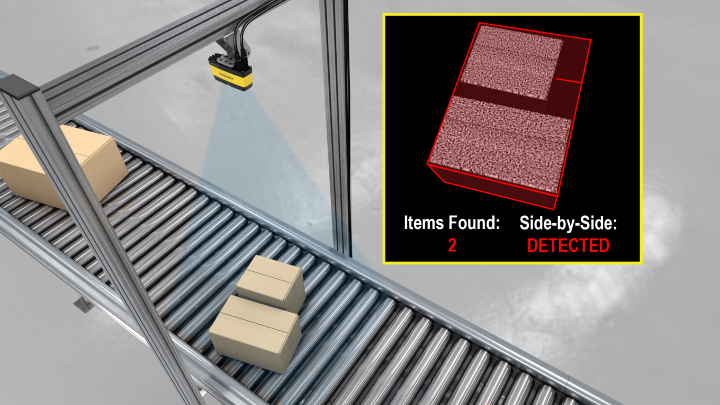

Verify tote volumes, confirm and validate label placements, inspect for product damage and check for side-by-side object detection to prevent duplicates in shipping.

Surface inspections

Carry out accurate inspections, even on challenging surfaces. Cameras come factory calibrated as standard, ready for factory integration by vision experts.

Powerful in-built features

Turnkey system includes Cognex vision tools, discrete I/O for pass/fail limits and speed tracking and gigabit ethernet connectivity with industrial Protocol support.

Product specifications

| Cognex 3D-A1000 Dimensioning System | |

|---|---|

| Technologies | 3D Symbolic Light |

| Trigger | Trigger input voltage limits 24 VDC Input ON: >10 VDC (>6 mA) Input OFF: <2 VDC (<1.5 mA) |

| Power | Voltage +24 VDC (22-26 VDC) Current 3 A max |

| 2D vision | 1280 x 960 resolution Modular external lighting & filter |

| Communication | GigE, TCP/IP, PROFINET, EtherNet/IP™, MS |

| I/O | 2 fixed inputs/ 2 fixed outputs |

| Operating temperature | 0-40℃ (32-104℉) |

| Protection | IP65 |