In-Sight 2800 detector for logistics

The In-Sight 2800 Detector is made for logistics, and is an ideal solution for carrying out inspections on high-speed lines and improving accuracy and quality control across logistics operations. We’ve been trialling it in the lab and the list of potential new applications it can solve is long, and growing.

Entry-level sensor that’s built for logistics automation

It’s an embedded sensor that adds really powerful, wide-angle lighting and polarisation – both of which are vital for automating logistics inspections accurately – and built-in edge learning to the existing 2800 deep learning camera.

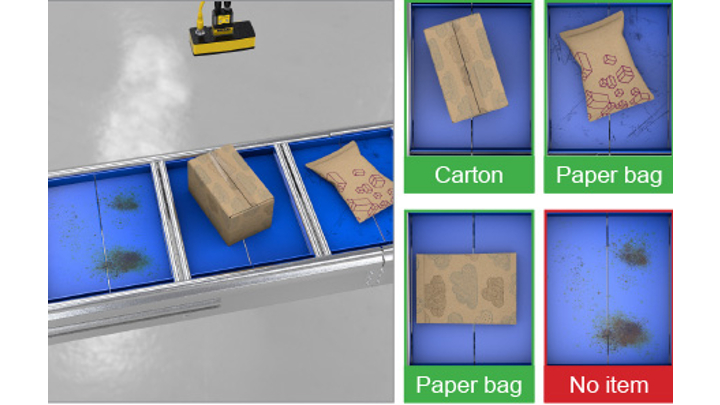

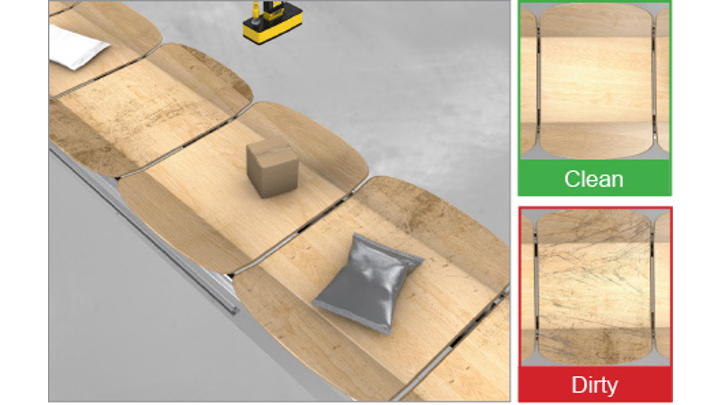

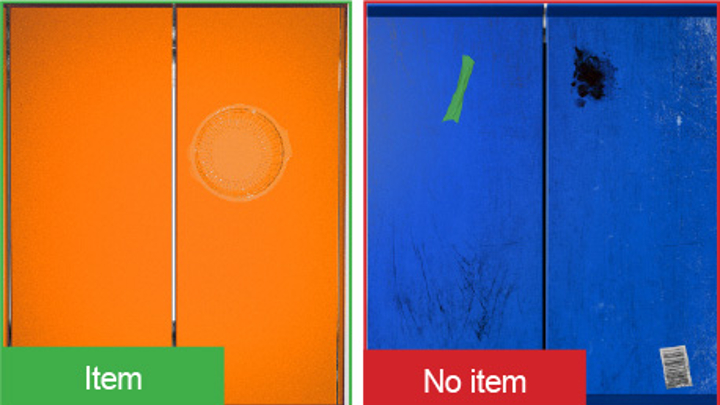

These, combined with with the built-in AI-based deep learning inspection tools, can detect and classify items with easy, spot potential problems such as spillages or jams and catch missorts sooner to prevent shipping errors.

Adds powerful lighting and polarisation to the popular 2800

Powerful embedded sensor

Catch small, subtle defects with deep learning-based error detection. Solve applications or classify parts with variation based on multiple defect types or user-defined features.

Detect, sort and process

Advanced Optical Character Recognition (OCR) uses AI-based edge learning to read characters on challenges surfaces – including uneven, reflective or low-contrast.

Optimise, train and deploy

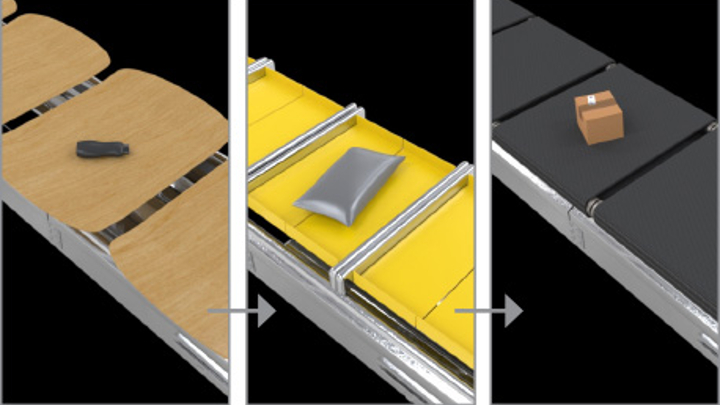

Train the In-sight 2800 detector with image examples to optimise inspection results, before deployment on new or existing sortation lines.

Integrate into existing lines

It can be retrofitted into a wide range of sortation lines, including roller conveyors, cross belts, tilt trays, rubber conveyors, bombays or more.

Challenging inspections

The 2800 detector works well across variations in item or background, to prevent false detections from damaged carriers or misplaced labels.

Solve industrial applications

Solve simple inspections, bespoke applications or complex logic sequences. ID, sort or classify parts by multiple characteristics or run multiple inspections with a single camera.

Product specifications

| Cognex In-Sight 2800 Detector | |

|---|---|

| Image Sensor | 1/2.8″ CMOS monochrome and color |

| Image Resolution Options | 1.6 MP (1440×1080) |

| Electronic Shutter Speed | Min. exposure 29 μs Max. exposure: Up to 3 ms (internal illumination) / Up to 200 ms (external illumination) |

| Lens Options | 6.2 mm High Speed Liquid Lens |

| Discrete Inputs | 2 opto-isolated |

| Discrete Outputs | 2 opto-isolated |

| Other I/O Points | 2 user configurable as inputs or outputs |

| Status Outputs | 5 status LEDs, audible beeper |

| Lighting | Polarised wide-angle white light |

| Communications | Serial and Ethernet interface |

| Protocols | TCP/IP, PROFINET, EtherNet/IP™, SLMP, OPC/UA/ FTP |

| Power | 24V ± 10%, 5A power supply recommended |

| Operating Temperature | 0-40℃ (32-104℉) |

| Protection | IP67 |