Infrared radiation (IR) or infrared light is a radiant energy that’s invisible to human eyes but that can be felt as heat. You can, however, use a thermographic (thermal imaging) camera to detect and monitor its presence.

Thermal cameras produce an image using infrared radiation – similar to a standard camera that forms an image using visible light. There are two types of thermal cameras available – thermal temperature cameras and thermal infrared cameras. If it’s essential to monitor temperature, then a thermal temperature (radiometric) camera is required, but if you simply need to see thermal energy then an infrared camera is the best solution.

When investing in a thermal camera, there are several important things to consider in order to determine reliability and results.

Questions to consider:

- What are you trying to see?

- What is the temperature of the object that you are trying to look at?

- What is the temperature of the surrounding area?

- How accurate do you need the temperature measurement to be?

- Do you need to monitor the temperature measurement or just be able to see the object itself?

- Is the object moving or is it stationary?

- How fast is it moving?

- Required frequency of inspection – how often do you need to inspect the object you are looking at?

- What material is the object you want to measure the temperature of?

- What is the surface finish of that material?

- Will the camera system be placed inside or outside?

These factors are crucial to ensure the success of an installation. Once your integrator has this information, they then can recommend a bespoke solution to best suit your needs.

The most popular type of thermal imaging camera is an uncooled LWIR camera. This guide explores the key factors to consider when purchasing an infrared camera as well as the possible applications and benefits.

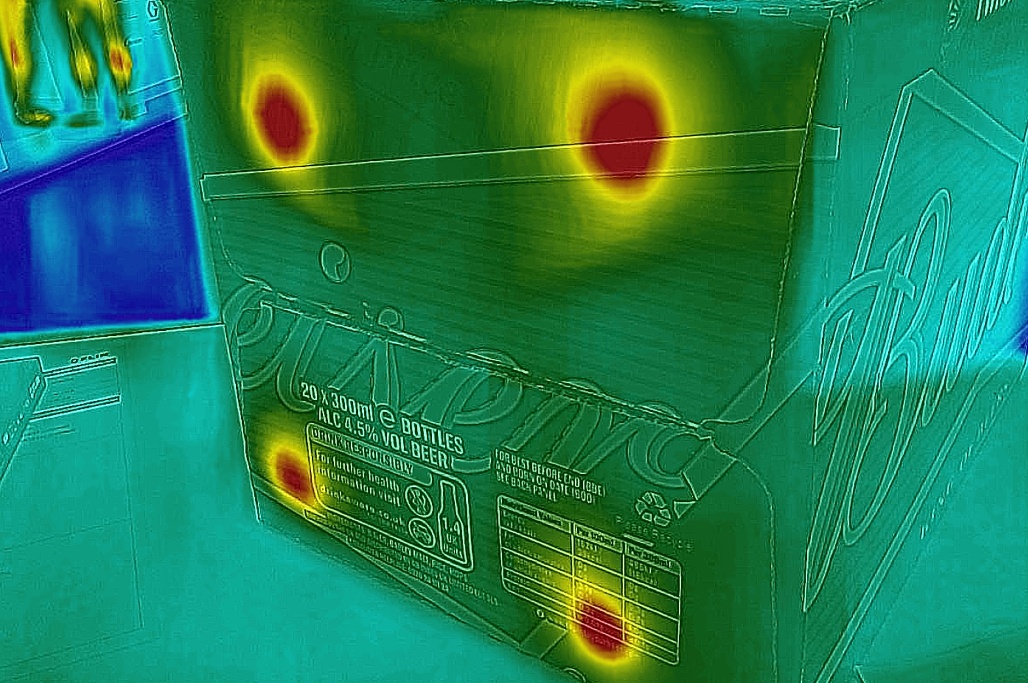

Understanding the capabilities of infrared cameras – Plastic-free packaging

Thermal cameras are often viewed with unrealistic expectations, created by television and film, and many businesses fail to understand their true potential. In reality, thermal infrared cameras can automate processes, increase accuracy, and safeguard facilities. In the case of our HotSpot system, they can help you go green by reducing plastic from your production lines (find out more).

Key factors to consider: Lighting and the environment

A major factor to consider when purchasing a thermal infrared camera is the environment it will be placed in and the outdoor lighting limitations. For example, if the camera is outside, is there likely to be a lot of reflections from the sun during daylight?

A great example of why environmental concerns are crucial is the use of infrared cameras for building fire detection in cladding installations. A lot of industry experts are proposing thermal imaging cameras as a good solution. However, when looking at the side of the building, if the sun happens to be at the right angle, at the right place, it can look like a 1,000 degree ball of fire in your images. Furthermore, if you have a rainy day and the sun suddenly comes out, it can look like the whole side of the building is a mirror. This increases the likelihood of false alarms which can be counter-productive.

Additionally, outdoor thermal infrared camera placements also face issues such as vehicle exhausts interfering with images. The heat of the exhaust can interfere with the reliability and accuracy of images – especially placed in an area with high volumes of traffic.

Key factors to consider: Indoor lighting and reflections

Indoor thermal camera placements are less of an issue in terms of lighting but the reflection of shiny metal in the vicinity or in the view of the camera would be extremely problematic.

Shiny metal will reflect anything hot which is nearby. For example, if you have a hot motor which happens to be in a reflective line of sight of the camera then you will see that hot motor in your image. Again, incorrect reflections and representations can significantly reduce the reliability, accuracy and success of thermal infrared camera systems.

Lighting and environmental issues like the above are extremely common. Many individuals purchase box ready cameras without having the experience or guidance to set them up correctly. This leads to disappointing results when the cameras fail to achieve the desired results.

It’s so important to speak to a vision expert before purchasing a thermal camera. A good integrator will be able to expertly set up thermal infrared camera systems in either indoor or outdoor environments and train your infrared cameras to recognise elements such as sunlight and exhaust or other high temperature components to prevent false alarms.

Cooled vs uncooled thermal infrared cameras

Consider the movement of the object you are monitoring – is it moving or static? This determines the type of camera you purchase. For moving objects, you will need a higher speed camera to be able to rapidly take accurate and sharp images.

There are two options in thermal imaging cameras – cooled or uncooled technology. If you’re not interested in precise accuracy, then an uncooled camera is sufficient. The majority of applications we deal with require an uncooled thermal infrared camera. It tends to be objects not moving particularly fast or projects which don’t require a high level of temperature monitoring accuracy. The priority is monitoring whether the object is hot or not.

For fast moving subjects or circumstances where you need high-levels of accuracy, or a sharper and better quality image, then a cooled camera is recommended. For example, stress analysis testing in materials would require a sharper image so the changes in the materials can be rapidly captured.

The importance of investing in the right technology

The price of a thermal camera system depends entirely on the level of accuracy and depth of monitoring required. There are many repurposed CCTV systems available, however, they will not produce accurate temperature readings.

There are a lot of CCTV based camera systems on the market which are promoted as thermal infrared cameras but in reality, they are being used for the incorrect application. This results in the technology not being fit for purpose and companies won’t achieve desired results.

Reliability and accuracy – Trusting a vision automation supplier

If you want to correctly invest in a thermal imaging camera, it’s best to speak to a vision automation specialist to make sure the system you’re purchasing will meet your specific requirements.

When you approach a potential company and explain your current issues and what you are looking to achieve, a good integrator will prioritise visiting your facility. They will bring a test kit and explore the environment to ensure you purchase the equipment necessary to achieve your results.

An experienced supplier will take a standard thermal infrared camera and adapt it to your unique requirements. They can also supply the software required to analyse the image as well as the necessary hardware for the camera setup and installation.

By having the camera installed and integrated by a professional company with extensive industry experience, your camera system is more likely to be reliable, accurate and a true asset to your business.